Hilectro robots are the ideal partners for automating standard injection molding processes. The optimization of production techniques combined with the selection of the best components enables an excellent price-performance ratio.

Hilectro robots are the ideal partners for automating standard injection molding processes. The optimization of production techniques combined with the selection of the best components enables an excellent price-performance ratio.

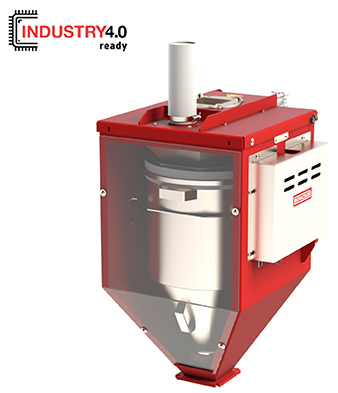

Drying of hygroscopic plastic materials for small throughputs. directly on the processing machines.

Maguire Vacuum Dryers are proven to dry polymers in a fraction of the time and with 60% less energy than desiccant dryers

The compact driers for smaller throughputs are cost efficient models. They work on time related regeneration for the drying agent and could handle drying silos from 100 to 400 litres.

The new dryer generation 2.0 by SIMAR features optimized energy effiency and an improved reliabilitiy of opration. The eDry combines these advantages with innovative control elements, which mirrow the straightforward controllabilitiy of the operation data. .

Accurate P.D. temperature control to achieve an even drying effect. Air-proofed insulative door can maintain temperature constantly inside to reduce energy consumption. Stainless steel tray and liner bring no contamination to materials.

Maguire Vacuum Dryers are proven to dry polymers in a fraction of the time and with 60% less energy than desiccant dryers

Crystallization The crystallization of PET PET - a semi-crystalline thermoplastic - is used in the production of high-quality bottles, films, fibres, tapes and other products. Depending on its subsequent use, its hygroscopic characteristics mean that this material must be dried at a temperature of 130°C to 180°C over a period of 4-6 hours before being thermally processed.

The highly efficient powerhouse Sprues and small faulty parts are shredded economically and quietly - adapted to your grinding task. Thanks to its footprint, the RS 150 takes up very little space and is ideal for integration into your injection molding machine. The 3-knife rotor ensures excellent regrind quality at a low cutting speed. Even soft plastics (e.g. TPE) are reliably processed into recyclable regrind.

Better slanted, well-tried thousandfold Into the large intake and then into the tilted rotor. There every kind of granulate is reliably granulated. The GRS granulators run in peak operation right from the start. prues of all kinds and small faulty parts are ground economically and quietly – adapted to your granulation need. The large cutting chamber opening in combination with the angled rotor makes the size reduction of bulky sprues possible. The GRS granulators can be equipped and adapted individually. Both models are available with low or high built frame. It is also possible to realize various rotor types or drive capacities. Tell us your application needs.

Productive residue recycler The compact central granulators of the new RS 2400 series have been specially designed for hourly throughputs of up to 220 kg and can be installed in the vicinity of the production lines.

Mid-market with a punch The ergonomically constructed granulators attain throughputs of up to 500 kg/hr in continuous operation depending on the model - whether in injection moulding operations or next to blow moulding machines.

Diversity on request The RS 3800 series is the logical refinement of the well-proven RS 2400 and RS 3000 and offers the same advantages. It is flexible in use thanks to various rotors, hoppers and peripheral equipment.

Devours large volumes quietly With the aggressive intake zone in the cutting chamber, seizes even thick-walled stock outages or large hollow shapes reliably; the noise level remains low.

True greatness, tailor-made The successful central granulator for all areas of plastic granulation. Unbeatable when it comes to granulation of large parts in the injection- and blow moulding sector. Makes short work of scrap web rolls, extruded plates, bumpers, thick-walled pipes or extruder scrap.

Even more of everything, for everything The biggest of the big. When tonnage is what counts, the RS 8000 is the granulator of choice. Equipped with an automatic feed system and regrind transport, it becomes a high-performance granulating center. A high level of automation simplifies maintenance and ensures high economy.

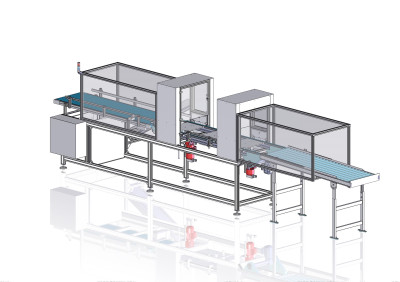

The FSA type separator is a screw separator with its own drive and is mainly used for the separation of injection molded parts and sprues

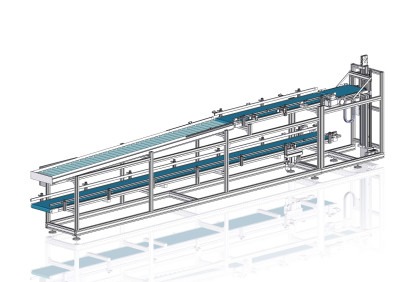

Cooling conveyor in stainless steel designed for cooling of medium to large size of moulded products with different density

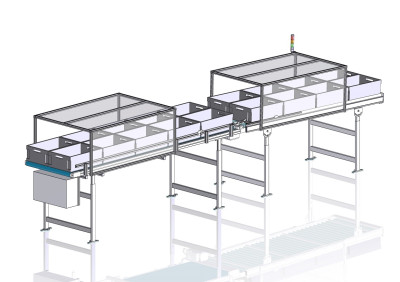

Filling conveyors are particularly suitable when it comes to the automatic filling of containers or cardboard boxes. This enables a smooth container changeover without causing machine downtime.

If there is a greater need for buffers, or if empty and full containers have to be loaded and unloaded on the same side, tiered storage systems with a lift are the ideal solution. In this way, the empty containers can be buffered on one floor and the full containers on the other floor.

Versatile system easy to assemble. Available in a wide range of combinations and sizes. Standard version has: structure in aluminium profiles, and galvanized steel rollers diam. 35mm. It can be use for different production sectors: material handling, packaging (food, pharmaceuticals…). Possibility of various solutions with motorized rollers.

Our tray stacking systems are similar to the BAKs. The empty tray stacks are fed in the empty area, separated in the destacking lifter and fed to the filling by the robot. After filling, the trays are stacked again and can be removed as full stacks in the full area. Tray stackers are configured by us on customer request in the most different variants, also e.g. with cross transfer or with lifter system as tier system and many more.

The turntable for automatic filling of boxes, containers or cartons. The containers are filled via a conveyor belt or a chute. Through the control in the turntable, a container change can be done by counting the parts or by setting a certain time. If a box or a carton has reached the number of pieces, the turntable automatically moves to the next container. The turntable can also be equipped with two levels. This causes a doubling of boxes / cartons.

The sorting chute is used to fill boxes, containers and boxes. The integrated control in the chute can initiate targeted indexing by counting the parts. If a box has reached the specified number of pieces, the sorting chute automatically moves on to the next one.

The MCBalance is the highest standard in gravimetric dosing. It proves its value on a daily basis in all branches, under all circumstances in injection molding, blow molding and extrusion. The dosing cylinder and patented weighing technology ensure extremely accurate dosing, even when low dosage rates are required. In this way, high savings on expensive additives can be achieved. The continuous loss-in-weight measuring feature and automatic motor speed adjustment are key to a stable production process. This guarantees high quality end products and fewer rejects.

Reusing rejects and sprues in the form of regrind can result in saving substantial amounts of colorant. The secret? Dosing masterbatch, powder, liquid or another additive and regrind simultaneously. One dosing unit of the MCTwin functions as the master unit and doses regrind, while the second operates in conjunction with the master unit and doses the additive. In practice this means that the more regrind is available, the less colorant is added. This enables you to avoid overconsumption of additives and to reuse the maximum of regrind. The process is fully automatic, so you always dose the maximum percentage of available regrind. The quality remains constant, production run after production run, 24/7.

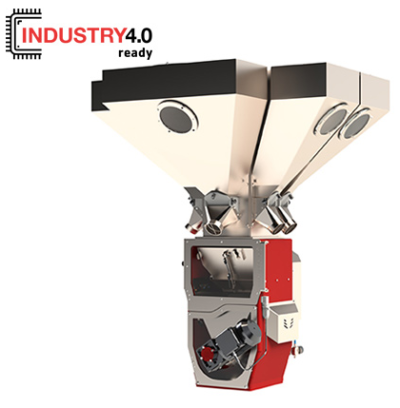

Home Products Gravimetric dosing MCHybrid 30 MCHybrid 30: the best of dosing and blending in one system The MCHybrid 30* is a unique dosing concept that combines two technologies into one system: batch blending and in-line dosing. The main materials or regrinds are mixed in an extreme compact gravimetric batch blender. Because the system only blends the main materials, the blending speed is high and therefore the batch blender remains small. The additives are dosed gravimetrically in-line, directly on the throat of the injection molding machine or extruder. By using these two blending and dosing technologies in one machine, you are able to control the main materials in any given ratio and at the same time dose additives at low percentages with unequalled accuracy.

Dyeing with liquid can be a challenge. It all depends on reliable dosing, often with extremely low dosing quantities. The most important issues are changes in the viscosity of liquids and leak-proof use. Movacolor has developed a modular liquid dosing system with a universal motor unit, two types of pumps and several leak-proof packaging concepts. This offers you the possibility to assemble the optimal configuration

MCPowder Dispensing powder is one of the biggest challenges in the dispensing field, especially when we are talking about heavy flowing powders in extremely low quantities. Expensive powder additives that have a big impact on your process require the best for precision and reliability. Based on its proven gravimetric technology, Movacolor has developed a compact powder dosing device precisely for this. It is able to dose very low with 100g / h, but also allows high dosages of up to 40 kg / h. The double spiral and funnel movement ensures problem-free dosing of the most difficult powders. And that applies to both injection molding and extrusion applications.

The revolutionary MCNexus is the new standard for dosing extreme small amounts of masterbatch. It is an ultra-compact dosing unit, able to dose pellet by pellet masterbatches or additives in various shapes and sizes. The working principle is simple. A standard compressed air supply creates vacuum via an air cardridge. A dosing disc captures the individual pellets piece by piece. Optional feature on the MCNexus is a mini hopper loader or a mounting bracket for air components (Air on Deck). Finally, the pellet is discharged with the same compressed air. Result: counting pellets with 100% accuracy. To reduce the number of components the MCNexus is manufactured by 3D printing. This gives the opportunity to customize the connection to the production machine.

Advanced mixing systems are often considered complete factory-developed solutions. Movacolor has developed a unique modular system that allows you to assemble a fully gravimetric, cohesive mixing system. Up to 15 components can be controlled by one control unit. These systems can be installed on one extruder or on multiple coextruders, creating a control platform for multiple interconnected mixers in one system. This system grows with your future needs.New components can be easily integrated without changes to the control unit. The MCContinuous Blender can handle most of the available materials, such as granulates, regrinds, powders and liquids.

The MCNumera is a modular measuring device which measures the consumption of main material in a production process.

Dosing powder is one of the most difficult tasks in the field of dosing. For your process, stability and quality control, as well as precise and reliable powder dosing, are often essential. And this under all circumstances.

The MCWeight is specifically designed to measure the actual filling capacity of an extruder. It has an integrated weighing module to accurately measure throughput and an integrated gate valve to control filling. Combined with one or more Movacolor devices, the MCWeight follows even the smallest capacity changes of the extruder. It adjusts the dosing of additives from the metering units accordingly. Dried material with a temperature of up to 180°C can be processed with the MCWeight.

The MCWeight P is designed to measure pourable powders, such as PVC dry mix. The MCWeight P can also be used for granular materials or castable regrinds containing dust. The design of the pneumatic blade opening is dust-tight. The sleeves are dust-tight, and there are additional dust filters for powder processing.

The MCHigh Output is the gravimetric solution to dose high capacities from 50 kg/h up to a maximum of 1,200 kg/h. The system meters this high additive output without making any concessions to precision. Gravimetric technology makes this possible for both injection molding and extrusion applications.

The MCHigh Output 2500R is a complete system that can fill low bulk density regrind at high feed rates. The unique design with a maximum mixing rate of 75% can be mounted directly on an injection molding machine or extruder. Gravimetric technology controls the metering rate and provides accurate material consumption data for traceability.

The MCHybrid 200 is a very compact and reliable batch blender, specially designed for processing a wide range of materials and regrind with a low bulk density. The MCHybrid 200 has a modular design and can be equipped with 2 to 8 components. The hoppers, made of robust stainless steel, with drains allow 100% emptying of the hoppers. With our unique valve design, even small components can be dispensed with an accuracy of up to 0.02%. The mixing chamber is equipped with a load cell, eliminating the need for a sensor. The weight mixing chamber can be used to measure the extruder throughput. The standard version of theMCHybrid 200 is suitable for processing materials up to 120 °C. A high-temperature version is also available that can process material up to 180 °C. If you want even more accuracy and flexibility or are looking for a compact design, you can also combine the MCHybrid 200 with our gravimetric inline metering units to get a unique hybrid blender.

The MC12 is together with the MC18 and MC30 our showpiece in volumetric dosing. These dosing units have proved their value since Movacolor started. The units are installed in factories all over the world and can operate under almost any conditions. Depending on the material, the unit can be tailor-made for dosing free-flowing powders, regrinds or normal granulates. The units add additive on the basis of volume. The MC12 unit is controlled by rpm setting. The Movacolor dosing cylinder® in combination with the stepper motor ensures maximum control with no stoppages or pulsations. The MC12 Economy volumetric in-line dosing unit is the entrance model of all Movacolor dosing systems for injection molding or extrusion.

The MC30 is together with the MC12 and MC18 our showpiece in volumetric dosing. These dosing units have proved their value since Movacolor started. The units are installed in factories all over the world and can operate under almost any conditions. Depending on the material, the unit can be tailor-made for dosing free-flowing powders, regrinds or normal granulates. The units add additive on the basis of volume. The MC30 can be pre-calibrated to dose at percentage rates. The Movacolor dosing cylinder® in combination with the stepper motor ensures maximum control with no stoppages or pulsations. The MC30 can be equipped with an automatic hopper loader for automatically filling the stainless steel hopper.

Sicherheitsvorhang verhindert das Unkontrollierte springen der Teile aus dem Werkzeugraum.

MCMicro is an ultra-compact dosing unit, especially developed for small injection molding machines. Its small size and the accurate stepper motor drive enable you to dose additives in-line on the smallest machines on the market. You can use the MCMicro for normal granulates and micro granulates. It is equipped with a quick release coupling, allowing easy color change. For different small injection molding machines we have adapters available. The MCMicro comes with a MC12 controller. The masterbatch hopper has a volume of 200 ml. The unit can also be supplied with an optional integrated hopper loader for the main material and MC18 controller. The main material hopper can contain 1.8 liter.

MRS industrial quality chillers are available in cooling capacity range from 13 to 75 KW, with water working temperatures from 0°C to 25°C and suitable for indoor or outdoor installation. The standard configuration is designed for an ambient temperature up to 45°C.

Kühlaggregate mit hohem Wirkungsgrad, konzipiert für den anspruchsvollen industriellen. Einsatz, die mit Komponenten von weltbekannter Qualität wie Schrauben- oder hochleistungstüchtigen Multi-Scroll-Verdichtern ausgestattet sind. Die integrierte programmierbare Steuerung gewährleistet auch unter extremen Umgebungsbedingungen eine zuverlässige Temperaturkontrolle.

Kühlaggregate mit hohem Wirkungsgrad, konzipiert für industrielle Anwendungen (selbst anspruchsvollste) und mit Qualitätskomponenten ausgestattet, die weltweit anerkannt sind, einschließlich Schraubenkompressoren mit hohem Wirkungsgrad. Die integrierte programmierbare Steuerung gewährleistet auch unter extremen Umgebungsbedingungen eine zuverlässige Temperaturkontrolle.

Water temperature controller available also in oil and water/oil versions, equipped with open tank, suitable to operate in pressure or in vacuum mode with working temperatures up to 90°C (water) or 150°C (oil). This temperature controller is available in various models: temperature controller with one heating element (TB-S), or with two heating elements and automatic partialization (TB-M), or temperature controller with double zones of thermoregulation (TB-D).

In the manufacturing industry, process reliability and product quality are always in the foreground. The formation of deposits in the water-carrying channels has a negative influence on tools and heat exchangers of any kind, e.g. B. by lime, rust or other dirt particles. By using the newly developed WRG tool cleaning device, these residues are removed quickly and easily with the aid of a specially developed acidic, environmentally friendly cleaning solution.

METRON 03 SL COMPACT PLATE METAL DETECTOR FOR THE INSTALLATION IN SMALL LOAD BELT CONVEYORS.

METAL SEPARATOR FOR THE INSPECTION OF GRANULES AND FLAKES IN FREE FALL

FOR INTERMITTENT VACUUM CONVEYING LINES

METAL DETECTOR FOR THE INSTALLATION IN PNEUMATIC CONVEYING LINES

Metal separator for installation in Free fall pipes

DIVERTIBLE TUNNEL METAL DETECTOR FOR INSTALLATION IN BELT CONVEYORS, VIBRATORY CHUTES AND MATERIAL SLIDES.

Hopper Loaders with single phase motor for smaller processing machines Manufactured from stainless steel and fitted with a hinged top, these models are easy to clean and maintain. The integrated acoustic hood of single phase conveying fan keeps noise level to a minimum. The programmable micro-processor control unit is designed for option such as mixer valve and cleanout valve which can be easily fitted at a later date.

The Venturi loader TOPfeed works according to the venturi principle and offers an easy feeding of small and medium sized processing machines with plastic pellets. It requires compressed air supply and is very easy to handle.

For the feeding of processing machines, day bins and drying silos. The separators AX2084 and AX2584 in a centralized vacuum conveying system are the economic form of supplying material to processing machines. Stainless steel design with hinged top, adjustable discharging flap with outside installed magnetic switch and an interchangeable feeding pipe enables feeding systems with a conveying duct of 38 and 50 mm. An integrated conveying valve can be used for interconnected conveying ducts with a troublefree function.

The new VISMEC dust separator is a device that removes dust from the plastic by static electricity and guarantees perfect quality on the final product. This is an innovative close-loop system that keeps dust and dirt from sticking to the electrostatically charged surface. The dust does not polymerize and creates impurities on the surface. The Vismec Dust Remover is therefore a must for high-tech and quality production and perfect for lens, medical and high-precision applications.

Silos mixer manufactured in iron with hopper for loading the granules from the bottom, with 500 lt. 16500 lt. capacity belt driver mixer tube and access door for cleaning.

Only consistent regrind in a defined grain size, dedusted and demetallised form, guarantees constant product respectively part quality. The different uncontrolled melting processes in the screw, with unequal material sizes will be avoided with our regrind material preparation.

For use with bulk goods in the plastic processing, food, chemical and pharmaceutical sectors. The best solution for handling BIG-BAGs, in order to bring the bulk goods to the processing machines by means of a suction conveyor

For use with bulk goods in the plastic processing, food, chemical and pharmaceutical sectors. The best solution for the handling of bagged goods, to bring the bulk goods to the processing machines by means of a suction conveyor

Outdoor and indoor silos for storing raw materials, mixed goods and finished products are a prerequisite for a meaningful automation of the material feed. In the food, chemical and plastics industries, silos made of aluminum are used almost exclusively today. They are corrosion and weather resistant, maintenance-free and have an unlimited shelf life. We offer storage silos made of aluminum or stainless steel for economical storage of raw materials with high throughput rates. Storage containers in sizes from 5 to 200 cbm are available, as well as silos with several chambers for storing different materials. The silos are equipped for loading by tank trucks. Alternatively, bag feeding stations with a high conveying capacity can be supplied.

Die neueste Version unseres Restfeuchte-Messgeräts zur Messung des Wassergehalts in Kunststoffen

Anschlussfertige Wassertank ab 1000 l Inhalt inkl.

Anschlussfertige Wassertanks ab 1000 l Inhalt inkl.

Automatic systems for film preparation: Whether solid films or die-cutting grids with or without thermoformed parts - the right infeed system masters the task. The RotoCutters with wide infeed are extremely quiet. Integrated into the thermoforming line, continuous and adapted film feeding is ensured.

Der Magnet für den Einfülltrichter gehört zu den Grundtypen von Magnetabscheidern und zeichnet sich durch einige Vorteile aus: einfache und schnelle Lösung, niedrige Investitionskosten, einfache Installation. Verwendet wird er vor allem in der Kunststoffindustrie bei der Verarbeitung von Regranulat oder zerkleinertem Material (Granulat). Er ist mit sehr starken Neodym-Magneten bestückt, die in der Lage sind, sehr kleine Metallverunreinigungen, die sich im Kunststoffgranulat befinden können, aufzufangen.

Fail-safe storage of system parameters Digital evaluation process for best results Process and condition monitoring Standardized system with a wide range of applications Robust design for long service life

The Getecha pre-cutters cut thicker sheet edge trims directly at the extrusion line.

suitable for separating pieces and sprues of different thickness, used in line at the machine exit with loading belt. The rotating separator unit is available in the roller version (manually controlled) or with perforated cover (with holes size to be defined).

to detach the pieces from the sprues, with variable speed through a handwheel. It is equipped with a conveyor belt with paddle or roller separator for the separation of the parts.

The Sweeper system is designed to automatically remove material from an Octobin container without the need for human intervention. The SWEEPER gets its name from the fact that it continuously "sweeps" the top level of the Octobin's contents to the outer edges. The material is sucked up by the rotating vertical pick-up tube assembly, which in turn comprises a rotating flexible hose and rod assembly. As the pick-up tube assembly rotates, the material is drawn into the manufacturing process through the vertical section

The product is continuously fed into the centre of the top screen, from where it spreads out evenly to the outside across the entire screening surface. The finer particles fall through the screen near the centre and the coarser ones successively towards the periphery. The material is moved in a spiral pattern with increasing acceleration of the particles the further they are from the centre, with the result that even those particles which are almost the same size as the screen mesh are screened. All the separated fractions are discharged through the lateral outlets. The screening process is repeated again and again on each deck.

Vibrating sprue separator made of stainless steel, which separates the sprues from the molded parts of different thicknesses. The separating unit is equipped with pipes that allow the parts to be separated through the vibration. A grinder for the sprues can be placed under the vibrator

Büchler GesmbH

Wipfinger Straße 23

3433 Königstetten

Austria