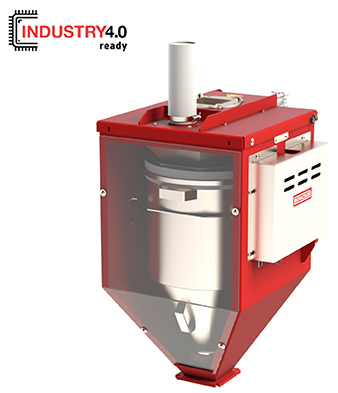

The MCBalance is the highest standard in gravimetric dosing. It proves its value on a daily basis in all branches, under all circumstances in injection molding, blow molding and extrusion. The dosing cylinder and patented weighing technology ensure extremely accurate dosing, even when low dosage rates are required. In this way, high savings on expensive additives can be achieved. The continuous loss-in-weight measuring feature and automatic motor speed adjustment are key to a stable production process. This guarantees high quality end products and fewer rejects.

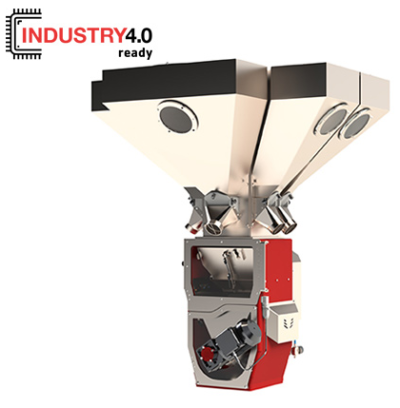

Reusing rejects and sprues in the form of regrind can result in saving substantial amounts of colorant. The secret? Dosing masterbatch, powder, liquid or another additive and regrind simultaneously. One dosing unit of the MCTwin functions as the master unit and doses regrind, while the second operates in conjunction with the master unit and doses the additive. In practice this means that the more regrind is available, the less colorant is added. This enables you to avoid overconsumption of additives and to reuse the maximum of regrind. The process is fully automatic, so you always dose the maximum percentage of available regrind. The quality remains constant, production run after production run, 24/7.

Home Products Gravimetric dosing MCHybrid 30 MCHybrid 30: the best of dosing and blending in one system The MCHybrid 30* is a unique dosing concept that combines two technologies into one system: batch blending and in-line dosing. The main materials or regrinds are mixed in an extreme compact gravimetric batch blender. Because the system only blends the main materials, the blending speed is high and therefore the batch blender remains small. The additives are dosed gravimetrically in-line, directly on the throat of the injection molding machine or extruder. By using these two blending and dosing technologies in one machine, you are able to control the main materials in any given ratio and at the same time dose additives at low percentages with unequalled accuracy.

Dyeing with liquid can be a challenge. It all depends on reliable dosing, often with extremely low dosing quantities. The most important issues are changes in the viscosity of liquids and leak-proof use. Movacolor has developed a modular liquid dosing system with a universal motor unit, two types of pumps and several leak-proof packaging concepts. This offers you the possibility to assemble the optimal configuration

MCPowder Dispensing powder is one of the biggest challenges in the dispensing field, especially when we are talking about heavy flowing powders in extremely low quantities. Expensive powder additives that have a big impact on your process require the best for precision and reliability. Based on its proven gravimetric technology, Movacolor has developed a compact powder dosing device precisely for this. It is able to dose very low with 100g / h, but also allows high dosages of up to 40 kg / h. The double spiral and funnel movement ensures problem-free dosing of the most difficult powders. And that applies to both injection molding and extrusion applications.

The revolutionary MCNexus is the new standard for dosing extreme small amounts of masterbatch. It is an ultra-compact dosing unit, able to dose pellet by pellet masterbatches or additives in various shapes and sizes. The working principle is simple. A standard compressed air supply creates vacuum via an air cardridge. A dosing disc captures the individual pellets piece by piece. Optional feature on the MCNexus is a mini hopper loader or a mounting bracket for air components (Air on Deck). Finally, the pellet is discharged with the same compressed air. Result: counting pellets with 100% accuracy. To reduce the number of components the MCNexus is manufactured by 3D printing. This gives the opportunity to customize the connection to the production machine.

Advanced mixing systems are often considered complete factory-developed solutions. Movacolor has developed a unique modular system that allows you to assemble a fully gravimetric, cohesive mixing system. Up to 15 components can be controlled by one control unit. These systems can be installed on one extruder or on multiple coextruders, creating a control platform for multiple interconnected mixers in one system. This system grows with your future needs.New components can be easily integrated without changes to the control unit. The MCContinuous Blender can handle most of the available materials, such as granulates, regrinds, powders and liquids.

The MCNumera is a modular measuring device which measures the consumption of main material in a production process.

Dosing powder is one of the most difficult tasks in the field of dosing. For your process, stability and quality control, as well as precise and reliable powder dosing, are often essential. And this under all circumstances.

The MCWeight is specifically designed to measure the actual filling capacity of an extruder. It has an integrated weighing module to accurately measure throughput and an integrated gate valve to control filling. Combined with one or more Movacolor devices, the MCWeight follows even the smallest capacity changes of the extruder. It adjusts the dosing of additives from the metering units accordingly. Dried material with a temperature of up to 180°C can be processed with the MCWeight.

The MCWeight P is designed to measure pourable powders, such as PVC dry mix. The MCWeight P can also be used for granular materials or castable regrinds containing dust. The design of the pneumatic blade opening is dust-tight. The sleeves are dust-tight, and there are additional dust filters for powder processing.

The MCHigh Output is the gravimetric solution to dose high capacities from 50 kg/h up to a maximum of 1,200 kg/h. The system meters this high additive output without making any concessions to precision. Gravimetric technology makes this possible for both injection molding and extrusion applications.

The MCHigh Output 2500R is a complete system that can fill low bulk density regrind at high feed rates. The unique design with a maximum mixing rate of 75% can be mounted directly on an injection molding machine or extruder. Gravimetric technology controls the metering rate and provides accurate material consumption data for traceability.

The MCHybrid 200 is a very compact and reliable batch blender, specially designed for processing a wide range of materials and regrind with a low bulk density. The MCHybrid 200 has a modular design and can be equipped with 2 to 8 components. The hoppers, made of robust stainless steel, with drains allow 100% emptying of the hoppers. With our unique valve design, even small components can be dispensed with an accuracy of up to 0.02%. The mixing chamber is equipped with a load cell, eliminating the need for a sensor. The weight mixing chamber can be used to measure the extruder throughput. The standard version of theMCHybrid 200 is suitable for processing materials up to 120 °C. A high-temperature version is also available that can process material up to 180 °C. If you want even more accuracy and flexibility or are looking for a compact design, you can also combine the MCHybrid 200 with our gravimetric inline metering units to get a unique hybrid blender.

The MC12 is together with the MC18 and MC30 our showpiece in volumetric dosing. These dosing units have proved their value since Movacolor started. The units are installed in factories all over the world and can operate under almost any conditions. Depending on the material, the unit can be tailor-made for dosing free-flowing powders, regrinds or normal granulates. The units add additive on the basis of volume. The MC12 unit is controlled by rpm setting. The Movacolor dosing cylinder® in combination with the stepper motor ensures maximum control with no stoppages or pulsations. The MC12 Economy volumetric in-line dosing unit is the entrance model of all Movacolor dosing systems for injection molding or extrusion.

The MC30 is together with the MC12 and MC18 our showpiece in volumetric dosing. These dosing units have proved their value since Movacolor started. The units are installed in factories all over the world and can operate under almost any conditions. Depending on the material, the unit can be tailor-made for dosing free-flowing powders, regrinds or normal granulates. The units add additive on the basis of volume. The MC30 can be pre-calibrated to dose at percentage rates. The Movacolor dosing cylinder® in combination with the stepper motor ensures maximum control with no stoppages or pulsations. The MC30 can be equipped with an automatic hopper loader for automatically filling the stainless steel hopper.

MCMicro is an ultra-compact dosing unit, especially developed for small injection molding machines. Its small size and the accurate stepper motor drive enable you to dose additives in-line on the smallest machines on the market. You can use the MCMicro for normal granulates and micro granulates. It is equipped with a quick release coupling, allowing easy color change. For different small injection molding machines we have adapters available. The MCMicro comes with a MC12 controller. The masterbatch hopper has a volume of 200 ml. The unit can also be supplied with an optional integrated hopper loader for the main material and MC18 controller. The main material hopper can contain 1.8 liter.

Büchler GesmbH

Wipfinger Straße 23

3433 Königstetten

Austria