The FSA type separator is a screw separator with its own drive and is mainly used for the separation of injection molded parts and sprues

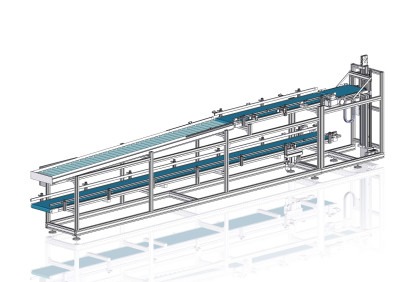

Cooling conveyor in stainless steel designed for cooling of medium to large size of moulded products with different density

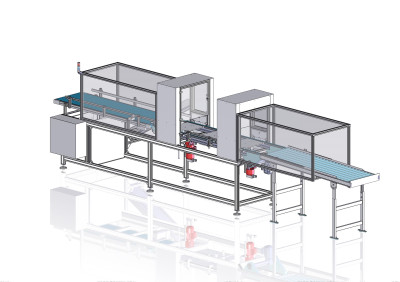

Filling conveyors are particularly suitable when it comes to the automatic filling of containers or cardboard boxes. This enables a smooth container changeover without causing machine downtime.

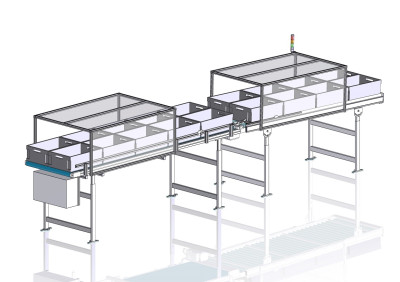

If there is a greater need for buffers, or if empty and full containers have to be loaded and unloaded on the same side, tiered storage systems with a lift are the ideal solution. In this way, the empty containers can be buffered on one floor and the full containers on the other floor.

Versatile system easy to assemble. Available in a wide range of combinations and sizes. Standard version has: structure in aluminium profiles, and galvanized steel rollers diam. 35mm. It can be use for different production sectors: material handling, packaging (food, pharmaceuticals…). Possibility of various solutions with motorized rollers.

Our tray stacking systems are similar to the BAKs. The empty tray stacks are fed in the empty area, separated in the destacking lifter and fed to the filling by the robot. After filling, the trays are stacked again and can be removed as full stacks in the full area. Tray stackers are configured by us on customer request in the most different variants, also e.g. with cross transfer or with lifter system as tier system and many more.

The turntable for automatic filling of boxes, containers or cartons. The containers are filled via a conveyor belt or a chute. Through the control in the turntable, a container change can be done by counting the parts or by setting a certain time. If a box or a carton has reached the number of pieces, the turntable automatically moves to the next container. The turntable can also be equipped with two levels. This causes a doubling of boxes / cartons.

The sorting chute is used to fill boxes, containers and boxes. The integrated control in the chute can initiate targeted indexing by counting the parts. If a box has reached the specified number of pieces, the sorting chute automatically moves on to the next one.

Hopper Loaders with single phase motor for smaller processing machines Manufactured from stainless steel and fitted with a hinged top, these models are easy to clean and maintain. The integrated acoustic hood of single phase conveying fan keeps noise level to a minimum. The programmable micro-processor control unit is designed for option such as mixer valve and cleanout valve which can be easily fitted at a later date.

The Venturi loader TOPfeed works according to the venturi principle and offers an easy feeding of small and medium sized processing machines with plastic pellets. It requires compressed air supply and is very easy to handle.

For the feeding of processing machines, day bins and drying silos. The separators AX2084 and AX2584 in a centralized vacuum conveying system are the economic form of supplying material to processing machines. Stainless steel design with hinged top, adjustable discharging flap with outside installed magnetic switch and an interchangeable feeding pipe enables feeding systems with a conveying duct of 38 and 50 mm. An integrated conveying valve can be used for interconnected conveying ducts with a troublefree function.

Büchler GesmbH

Wipfinger Straße 23

3433 Königstetten

Austria